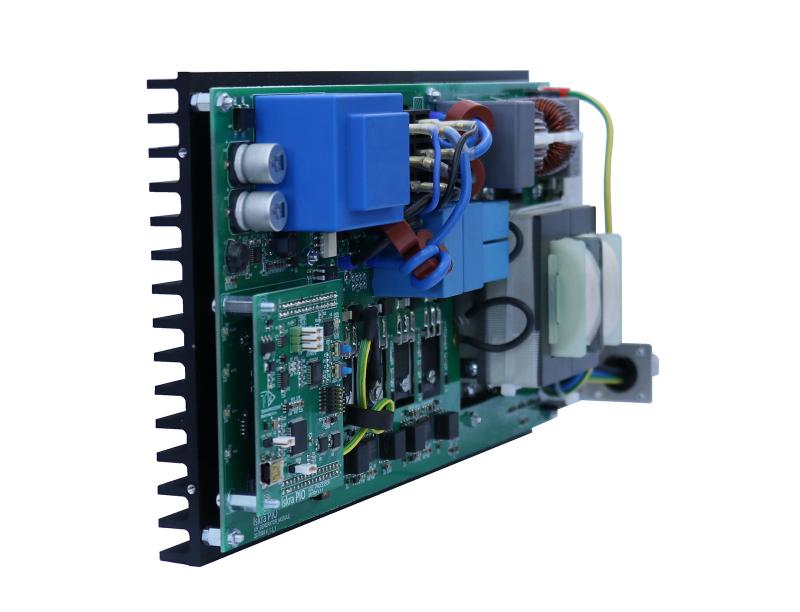

UZG1500, UZG2000

The UZG1500 and UZG2000 ultrasonic generators operate at frequencies between 25.5 kHz and 28 kHz.

Related productsThe ultrasonic generators convert the voltage / frequency of 50 Hz from the power supply units into a signal of appropriate amplitude / frequency. The name "ultrasonic" dictates frequencies above 20 kHz. Frequencies from 26 kHz up to 1 MHz are used for cleaning. At a lower frequency, cavitation bubbles have more time to grow, so they are larger than at a higher frequency. Consequently, shock waves that remove dirt are also stronger. At higher frequencies, smaller cavitation bubbles are generated with less intensity, but their number is larger. Cleaning the stubborn dirt is therefore in the lower frequency domain. A higher frequency is used to clean more sensitive items with less degree of soiling, or where smaller cohesion forces are present during the dirt itself, or between the dirt and the cleaned item. The corresponding amplitude ensures a sufficiently large expansion and contraction of the ceramics of the transducers, which in this way convert the electrical energy into mechanical energy. The contraction and expansion appeared to be as oscillation on the outside, which is transferred to the liquid through the bath. These conditions, of course, with a sufficiently high frequency and amplitude of oscillation, create cavitation. However, for the cleaning efficiency, the frequency and amplitude are often not in themselves sufficient. Certain functionalities the generator can offer are also very important.

The UZG1500 (1500 W) and UZG2000 (2000 W) generators operate at frequencies from 25.5 kHz to 28 kHz. The frequency of operation is adjusted accordingly to the conditions of the bath itself. This is provided by the periodic search function of the optimal frequency. In specifying the period, incorrect adjustment can be avoided at the moment of expected unstable conditions (example: automatic transport moves the basket in the bath, vertical oscillation of the basket, ...).

By generating a floating frequency, the UZ generator provides a more homogeneous cavitation distribution within the bath. Thus, in the bath, there is no occurrence of dead places where the cavitation is significantly reduced (less washed pieces) and places where the cavitation is stronger (possible damage). In addition, there is no excitation of sheets (higher harmonics) and consequently higher noise. The term "sweeping frequency" refers to the periodic variations in the operating frequency within a narrow bandwidth up to a few 100 Hz. A larger band is not desirable as the output power of the converters may be reduced. On top of all, the sweeping frequency makes each transducer reach its maximum power at some point in the period. Namely, because of non-ideal materials, production processes, ... the transducers are not identical among themselves (resonance frequency value, impedance, ...).

Degassing accelerates the elimination of gases trapped in the liquid itself. The gases get trapped in the bubbles during ultrasound operation, but ultrasound at the same time makes the gases more difficult to get out to the surface. Therefore, the degassing function of the ultrasound works intermittently.

For connectivity to other devices, controllers, or control elements, the generator with three implemented digital inputs and three digital outputs can be configured. The generator can also be easily upgraded with one analog input and output (voltage or current), which allows the power to be controlled by the controller. Communication with the generator is also possible via RS485 communication.

The adaptation of the generator to the ultrasonic transducers themselves, as well as the setting of the parameters, is easily carried out with the help of a computer.

The generator provides the following settings:

- Operating frequency range

- Period and amplitude of the sweeping frequency, which ensures homogeneous dispersion of ultrasonic energy within the bath

- Setting of the gasification parameters, in which gases trapped in the liquid are more rapidly released, thereby weakening the cleaning effect

- Selection of operating mode (Automatic / Manual)

- Power of operation

- Configuration of digital inputs / outputs

- Configuration and calibration of analog inputs / outputs

- Adjustment of current, temperature protection, and other safety mechanisms

- Recording and reading of service interventions stored on the generator itself

- Measurement and recording of several parameters in real time

- Manual measurement and manual determination of the optimum operating frequency band

- Automatic periodic determination of the optimum operating point with the possibility of setting the frequency range, the number of samplings, the determination period, and the power at which sampling is performed

- Diagnostics