New generation of digital ultrasonic cleaners facilitate a better adjustment to meet the needs of the most demanding users. The entire series has integrated piezo transducers that provide a 40 kHz operating frequency. This ensures a lower noise level and a more efficient cleaning of more sophisticated products. Automatic adjustment of the operating frequency according to the conditions of the bath is also important. Thus, an optimum cleaning effect is always present within it. The degassing function, which speeds up the process of extracting gases from the cleaning liquid, is also not missing. The presence of trapped gases in the liquid makes it impossible to create ultrasonic cavitation, which weakens the cleaning effect.

It is possible to operate it via a foil keyboard using an LCD graphic display. Operation is available in the following languages: Slovenian, English, German and Croatian. The main screen allows simultaneous display of actual and set parameters such as temperature, operating time and power (only set value display). The main screen also shows information such as the status of the heater and the UZ generator. The temperature can be set up to 80 ° C and the maximum operating time is limited to 99 minutes and 59 seconds. The power can be adjusted from 10% to 100%, which can come in handy when cleaning sensitive items such as ceramic, glass, ...

In addition to the parameters already mentioned, it is also possible to set the output signal format (12 shapes) and floating frequency parameters. The proper output signal shape, depending on the object to be cleaned and the type of soiling, can speed up the cleaning time as well as the final purity. A sweeping frequency that can be adjusted for both the period and the width of the offset ensures a more homogeneous distribution of cavitation within the bath. Thus, in the bath there is no occurrence of dead zones where the cavitation is significantly reduced (less washed parts) and places where the cavitation is stronger (possible damage). The term "sweeping frequency" refers to the periodic variation of the operating frequency within a narrow bandwidth up to a few 100 Hz. · A larger band is not desirable as the output power of the converters may be reduced. On top of that, the sweeping frequency ensures that each transducer glued to the bath reaches its maximum power at the given moment of time. Namely, because of non-ideal materials, manufacturing processes, ... the transducers are not exactly the same (resonance frequency, impedance, ...)

Optionally, a remote start connection for the ultrasonic generator can be installed, for example when the ultrasonic bath is placed in a noise chamber.

Technical data

|

Type |

Frequency mode in kHZ |

VF peak power per period v W |

Power supply in W |

Heating |

Drain |

Weight in kg |

|

Sonis 3 DT |

40 |

320 |

80 |

NO |

NO |

3,6 |

|

Sonis 3 DGT |

40 |

320 |

180 |

YES |

NO |

4,0 |

|

Sonis 4 DT |

40 |

400 |

100 |

NO |

YES |

6,0 |

|

Sonis 4 DGT |

40 |

400 |

300 |

YES |

YES |

6,7 |

|

Sonis 10 DT |

40 |

600 |

300 |

NO |

YES |

9,5 |

|

Sonis 10 DGT |

40 |

600 |

700 |

YES |

YES |

10,2 |

|

Sonis 20 DT |

40 |

1200 |

600 |

NO |

YES |

15,8 |

|

Sonis 20 DGT |

40 |

1200 |

1300 |

YES |

YES |

16,7 |

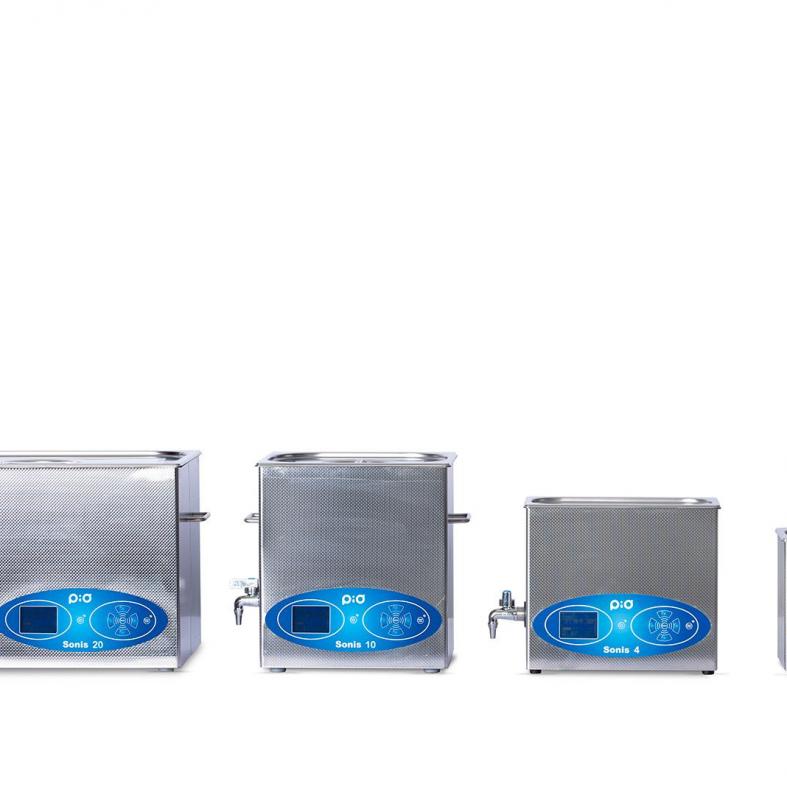

Dimensions

|

Type |

Bath, inside dimensions LxWxH in mm |

Bath, outside dimensions LxWxH in mm |

Volume in l |

|

Sonis 3 |

240x137x100 |

265x190x230 |

2,8 |

|

Sonis 4 |

300x150x150 |

325x205x280 |

5,7 |

|

Sonis 10 |

300x240x200 |

370x320x350 |

12,5 |

|

Sonis 20 |

500x300x200 |

580x380x350 |

28 |

All the exterior elements are made of stainless steel, which guarantees a longer service life.

Additional equipment

- Stainless steel covers

- Flanges for flasks

- Glassware

- Round baskets

- Cooling pipes

- Baskets

- Partitions